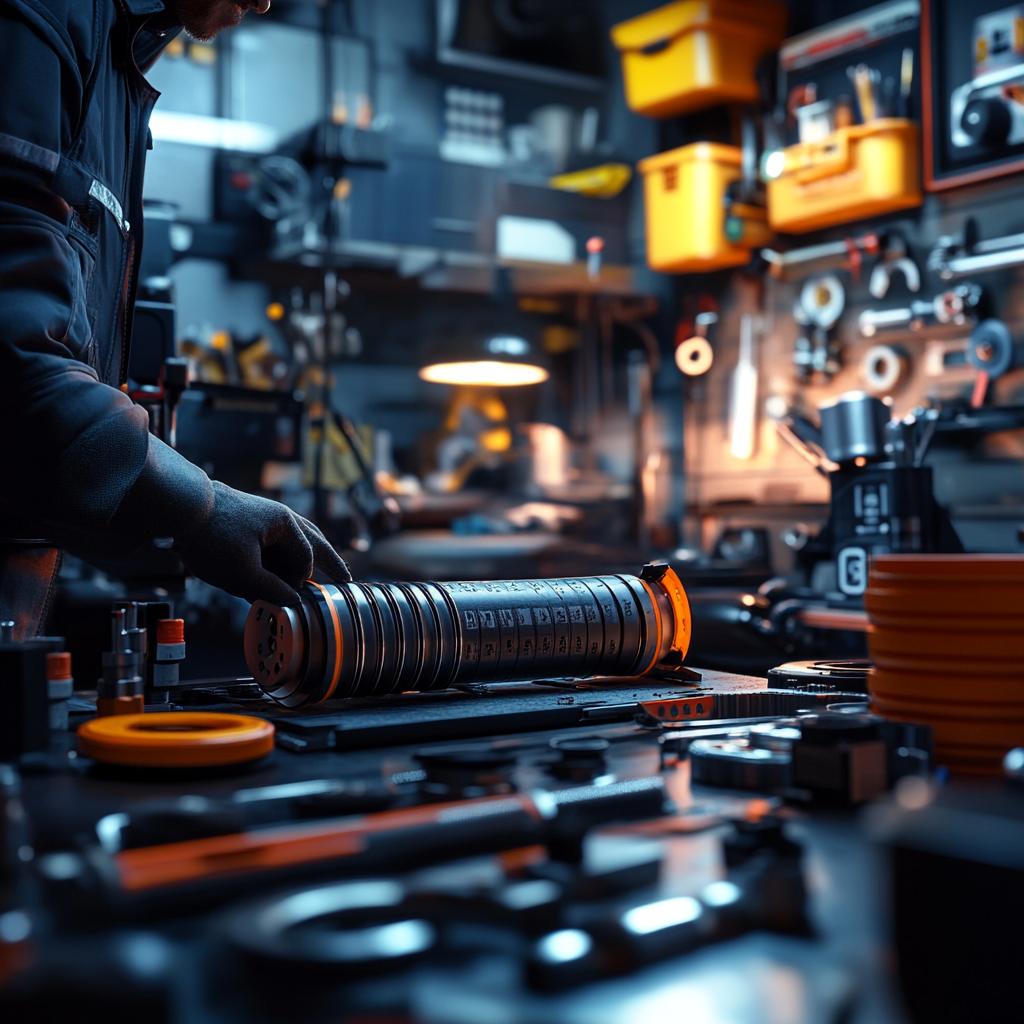

Step-by-Step Guide: Measuring Driveshaft Length Accurately

Accurately measuring the driveshaft length is crucial for ensuring a well-fitted and smoothly functioning driveline. A slight error in measurement can lead to vibrations, increased wear on drivetrain components, and possible failure. This guide will walk you through the step-by-step process of measuring your driveshaft length accurately, ensuring your drivetrain performs optimally.

Why Accurate Driveshaft Measurement is Important

The driveshaft is a critical component that transmits torque from the engine to the wheels. Proper length is essential for:

Improperly sized driveshafts can cause significant damage to your vehicle, leading to costly repairs.

What You Will Need

Before getting started, gather the following tools to ensure an accurate measurement:

Safety First

Before lifting the vehicle, ensure safety precautions are in place:

Safety is paramount. Always prioritize your well-being over speed.

Step-by-Step Measurement Process

Step 1: Lift the Vehicle

For vehicles with limited ground clearance, use a jack to lift the vehicle. Ensure it’s securely on jack stands before proceeding. Leave sufficient space for you to move and measure comfortably.

Step 2: Identify Measurement Points

Locate critical measurement points:

These points will serve as reference points for your measurement.

Step 3: Position the Measuring Tape

Extend your measuring tape from the face of the transmission output shaft to the face of the differential yoke or flange. Ensure the tape is straight and not twisted for an accurate measurement.

Step 4: Take the Measurement

Record the distance from the end of the transmission output shaft to the base of the differential yoke or flange. Note this measurement carefully.

Step 5: Accounting for Compression

Consider the driveshaft’s ability to compress and extend during vehicle operation. Typically, a half-inch allowance is necessary to accommodate these movements.

Tip: Subtract half an inch from your recorded length to ensure a proper fit.

Step 6: Record Final Measurement

Write down the adjusted length, which accounts for the compression allowance:

Adjustment Formula: Final Length = Recorded Length – 0.5 inches

Final Check and Double Verification

To ensure accuracy:

This final step prevents errors that can cause driveline issues.

Common Challenges and Solutions

Dealing with Limited Space

If the space under your vehicle is cramped:

Measuring Irregular Surfaces

For irregular yoke surfaces:

Expert Tips for Accurate Measurement

Consistency is Key

Always measure at the same points. Consistency ensures reproducibility and avoids discrepancies.

Use Quality Tools

Invest in high-quality measuring tools to minimize errors and enhance precision. Cheap tools can lead to unreliable measurements.

Document Everything

Keep a detailed record of your measurements, including any adjustments. This documentation assists in future reference and avoids repeat measurements.

Conclusion

Measuring your driveshaft length accurately is essential for a well-functioning vehicle. By following this step-by-step guide, you can ensure precise measurements that prevent driveline issues and maintain your vehicle’s performance. Remember to prioritize safety, use quality tools, and double-check your measurements for the best results.

Accurate driveshaft measurement is not just about getting the numbers right; it’s about enhancing your vehicle’s lifespan and performance. Follow the steps carefully, and you’ll have a smooth-running driveline that lasts for years.